Tao Zhang1, Yang Zhao1, Fuhui Wang1

1Northeastern University, 3-11 Wenhua Road, Shenyang, 110819, China

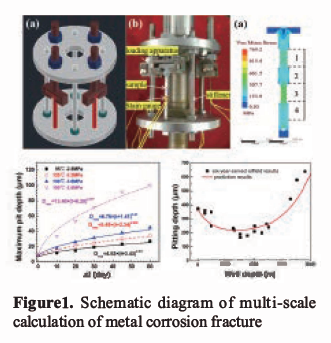

EXTENDED ABSTRACT: The increasing demand for resources has shifted the exploration towards ultra-deep oil wells at Tarim oilfield in the Northwest of China [1]. Oil Country Tubular Goods (OCTG) are in the oilfield environment, which is conducive to corrosion. The development of a theoretical model to predict corrosion damage of HP-13Cr SS in the extremely oilfield environments has become necessary. However, the modeling became a challenge for corrosion under complex coupling environments due to which, the model required further reconstruction. A schematic of the corrosion rotating cage with various stress levels is displayed in Fig. 1. The constant tensile stress area exhibited a stable flow rate, which indicated that the T-type sample and the stress corrosion rotating cage could be used to simulate the stress, flow rate and the coupling experiments. A multi-degree of freedom mechanistic-chemometrics model for predicting the pitting damage ofHP-13Cr stainless steel is developed by combining the mechanistic models and chemometrics method.The mechanistic model is reconstructed by considering the effect of single factors, such as high temperature, high CO2 pressure, flowrates and complex stress distribution. The single mechanistic models are combined together considering the weight coefficients of variable interaction using the chemometrics method. Finally, in order to verify the accuracy of mechanistic-chemometric model, the predicted results are compared with the field data of HP13Cr SS well after being used for six years in the Tarim area.

Keywords: Genetic engineering of materials; stainless steel; corrosion prediction; oil & gas corrosion

REFERENCES

[1] H Pang,J.Q.Chen,X.Q. Pang, L.F.Liu, Mar Petrol Geol 43(3),(2013) 88-101

Tao Zhang has completed his PhD at the age of 29 years from institute of Metal researches. He is the professor of Northeastern University. He has published more than 90 papers in reputed journals and has been serving as an editorial board member of Corrosion Communications.