Haitao Wang1*,En-Hou Han1,2

1Institute of High Energy Physics, Chinese Academy of Sciences, Beijing 100049, China

2Spallation Neutron Source Science Center, Dongguan 523808, China

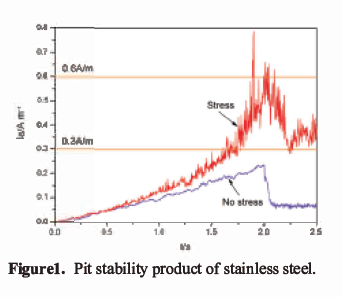

EXTENDED ABSTRACT: Pitting corrosion is one of the most destructive and insidious forms of corrosion damage. It is generally considered that pitting corrosion occurs in three stages: nucleation, metastable growth and stable growth. The metastable growth is a very critical stage of pitting corrosion because only pits that survive this stage become stable growing pits. A cellular automata model is used to describe pitting corrosion damage. The model includes anodic dissolution rule, passivation rule, hydrolysis rule of salt film, accelerated diffusion rule and mechanochemical interaction rule. A distributed parallel algorithm of cellular automata is developed based on message passing communication, and an automated process job is designed to run 102 high-throughput computing. The result shows that the increase of the rupture time of pitcover, the decrease of the diffusion coefficient of hydrogen ions and the decrease of the rupture extent of pit cover can cause the metastable pit toenter the stable growth. In the same conditions, the metastable pit under stress comes to stable growth more easily than that under no stress, and the corrosion pit interactions can also promote the metastable pit transition. The analysis of the pit stability product shows that the simulation results are in close agreement with the experimental conclusions.

Keywords: stainless steel; pitting corrosion; cellular automata; MPI; parallel algorithm

[1] H. T. Wang, E. -H. Han, Carros. Sci., 103 (2016) 305-311

[2] S. Guo, H. T. Wang, E. -H. Han, J. Electrochem. Soc., 165 (2018) C515-C523

[3] J. Schuchart, P. Samfass, C. Niethammer, J. Gracia, G. Bosilca, Parallel Comput., 106 (2021) 102793

Dr. Haitao Wang is principal investigator at Institute of Corrosion Science and Technology. His research interest is focused on multiscale modeling and simulation of corrosion. He published more than 45 peer-reviewed papers, and hold 11 software copyrights and 4 invention patents. He is now the Topic Editorial Board Member of"Materials", Subject Editor of"Chinese Journal of Engineering", and Editorial Board Member of"Materials for Mechanical Engineering".