Guohua Fan1,2*

1Nanjing Tech University, Nanjing, 211816, China

2Yangtze Delta Region Institute of Advanced Materials, Suzhou, 215000, China

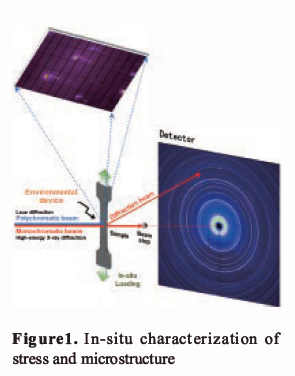

EXTENDED ABSTRACT: The synchronous enhancement of strength and plasticity is one of the eternal themes in the study of metallic structural materials. In this report, from the perspective of multi-scale stress characterization, it is initially found that "stress regulation" can be the key to understand the strength-ductility constitutive relationship of metallic materials. This report focuses on the study of laminated metals, magnesium alloys, and additive manufacturing components. Stress analysis techniques at the nanoscale are developed based on high-resolution transmission electron microscopy and geometric phase analysis. The focused ion beam - digital image correlation . stress analysis technique is developed based on double beam scanning electron microscopy, using focused ion beam and digital image to replace conventional analysis methods of milling and strain gauge measurement to achieve accurate stress characterization on the micron scale. Based on the advantages of high penetration of synchrotron radiation and neutron sources, a component-scale stress detection method has been developed. By constructing in-situ fabrication and in-service environments such as solidification, sintering, ultra-high/low temperature, mechanics, corrosion, etc., the tracing of the stress evolution pattern of the whole life cycle of the component is realized. Fig. 1 shows the stress and microstructure characterization by coupling synchrotron radiation and in-situ service environment. The Debye Scherrer diffraction ring, which includes information of grains with different orientations, can be obtained by using monochromatic incident beam with transmission diffraction geometry, and the lattice strain of the component can be calculated from the distance between the diffraction ring and the diffraction center to deduce the stress field; the Laue diffraction pattern, which includes information of several grains, can be obtained by using polychromatic beam with reflection diffraction geometry. The position of the diffraction spots indicates the orientation of the grains. The shape and size of the diffraction spots are closely related to the type and density of dislocations in the grains. In combination with the in-situ enabling environment, it provides a new vision for the analysis of the service behavior of the components. This report focuses on combining multi-scale stress and microstructure characterization of metallic materials, analyzing key deformation microstructure features such as dislocation structure, twinning, slip band and shear band during deformation, establishing the relationship between stress and deformation microstructure, and guiding the design and development of high-performance metallic materials and components.

Keywords: metallic materials; deformation; strength; ductility; local stress

1

1

Prof. Guohua Fan, graduated from Harbin Institute of Technology, is a national talent, Jiangsu Province "double-innovation talent" (key support), executive deputy director of Jiangsu Province Advanced Lightweight and High Performance Materials Key Laboratory, executive deputy director of Nanjing University of Technology Advanced Lightweight and High Performance Materials Research Center, and project leader of the National Key R&D Program. His research interests include the deformation and strengthening of metallic materials and advanced characterization technology. Based on advanced characterization techniques such as in-situ electron microscopy, synchrotron radiation, and neutron diffraction, he has built a complete research system of "basic theory - characterization device and method - demonstration and verification on key materials" to realize the application of advanced metallic materials in manufacturing. He has published more than 80 academic papers, including 17 papers in top journals such as Progress in Materials Science (1), Acta Materialia (7), and Scripta Materialia (6), with more than 2500 citations in SCI. He has hosted two National Key Research and Development Program projects and three National Natural Science Foundation of China projects.